|

|

|

|

|

T-shirt bag |

D-cut bag |

|

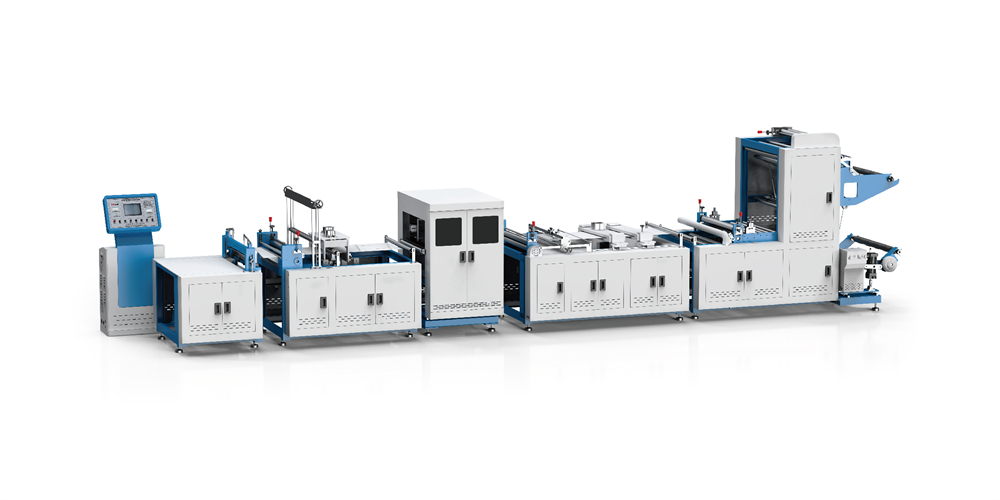

Part 1 Fabric roll Feeding part |

||

|

|

|

|

Max width of unwinding 1600MM, max diameter of unwinding 1000MM Auto feeding, Photocell eye tracking, Auto rectifying deviation, Magnet powder tension control,folding sealing by ultrasonic welding, custom made round embossing mould. |

||

|

Part 2 Folding part |

||

|

|

|

|

| Non woven fabric cross folding device, easy adjustment, which make the bog mouth neat and tidy even without moving the whole machine. | ||

|

Part 3 Bag bottom / side Gusset part |

||

|

|

|

| Double Ultrsonic sealing ,bottom and side gusset making, and the side sealing of T-shirt bag by ultrasonic. | ||

|

Part 4 Bag making part |

||

|

|

|

| The function of Bag side sealing , cutting, collection. adjustable photoelectric sensor for printing color mark tracking and Durable cold cutter. Adopts two Taiwan brand ultrasonic welding system(horn 350 MM) , different specs of ultrasonic can be used to meet different non woven fabric GSM. | ||

| Part 5 Auto T-shirt bag Punching | ||

|

|

|

| Double line Online auto punching , Clamping bag, mould stamping into T-shirt bag. | ||

| Part 6 Operation Computer | ||

|

Integrate all the electricity elements, adopts split-type design and PLC motion control as well as touch screen man-machine interface,easy operation and maintaining. |

|

BAG TYPE--- ZXL-A800 machine can make :

|

Non woven T-shirt bag / Vest bag/ W-cut bag / U-cut bag(Making online) |

|

Bag Height: 200-700mm Bag Width: 200-300mm Bag Guesst: 30-80mm |

|

|

Non woven D-cut bag ( Making online) |

|

D-cut bag with or without bottom Bag Height: 250-580mm Bag Width: 100-800mm Bag Folding: 30-80mm Bag Bottom Guesst: 20-80mm |

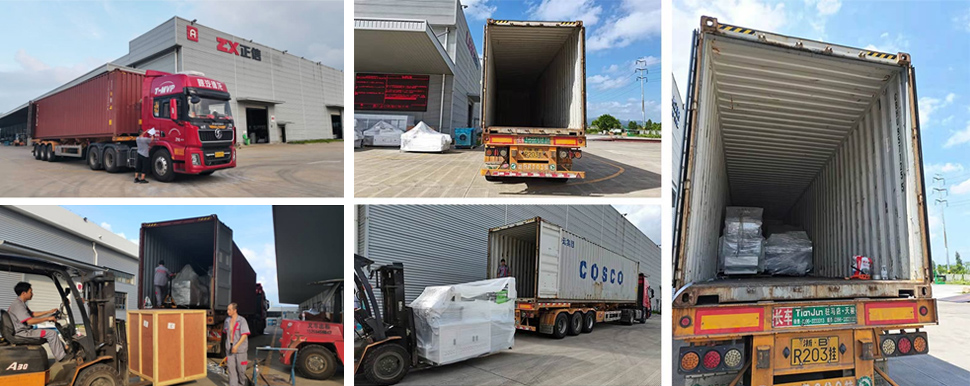

Weight: 3000KGS

Container : one 40ft container and one

Packing: In containers, and packed with plastic films (Wooden case / Wooden pallet also available)

Shipping Mark: N/M ( depends on customer demands)

Our packaging is very strict. Please rest assured.