|

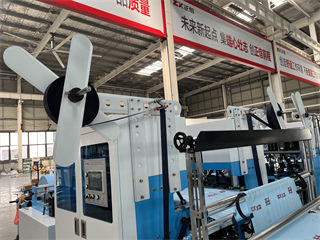

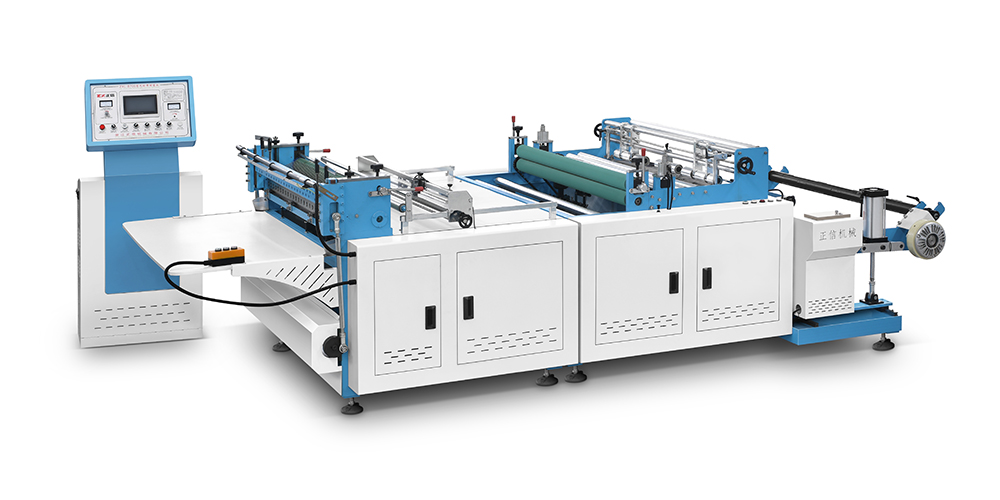

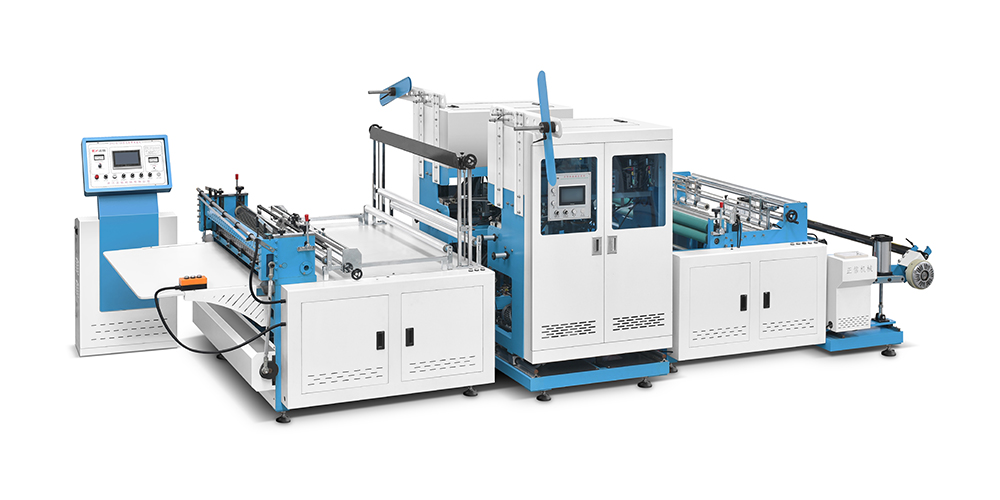

Part 1 Fabric roll Feeding part |

||

|

|

|

|

Equiped with Photocell eye tracking, Auto rectifying deviation, Magnet powder tension control,folding sealing by ultrasonic welding, custom made round embossing mould. |

||

|

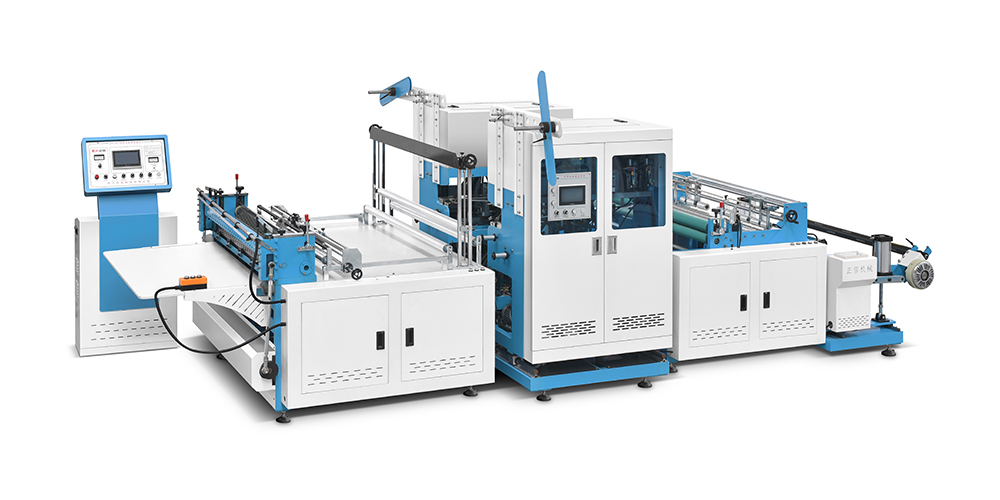

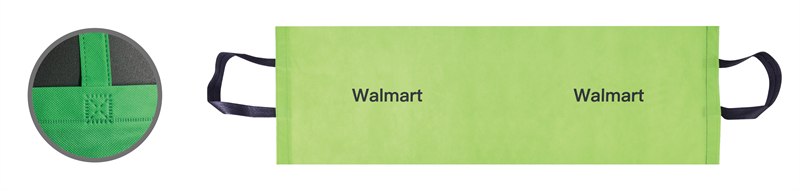

Part 2 Online double side soft handle sealing |

||

|

|

|

|

| The function of welding the double handle loop on the material by 2 side handle sealing machine . it’s mainly used in the producing of manual non woven sealing bag , wine and git bag etc. | ||

|

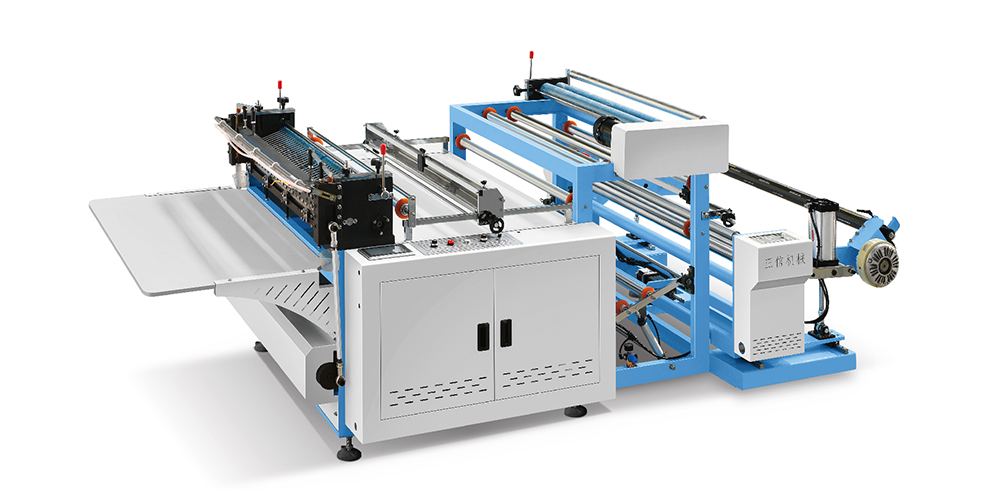

Part 3 Finished product collecting part |

||

|

|

|

| Adopts quality cutting knife , wear-resistant, durable, product cutting is tidy and beautiful. | ||

|

Part 4 Operation Computer |

||

|

|

|

| Integrate all the electricity elements, adopts split-type design and PLC motion control as well as touch screen man-machine interface, easy operation and maintaining. | ||

Las principales variables técnicas:

|

Velocidad de producción |

30-70pcs/min |

|

Bolsa ancha |

500-1100mm |

|

Bolsa alta |

280-800mm |

|

Espesor del material del mango |

60-100g/㎡ |

|

Longitud del ciclo del mango |

380-600mm |

|

Bolsas cuantitativas |

35-120g/㎡ |

|

Fuente de alimentación |

380V/220V |

|

Potencia total |

13KW |

|

Dimensiones (L * W * H) |

6500×2300×1800mm |